Polyethylene Blown Film Extrusion . blown film processing. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. The first step in blown film manufacturing is extrusion. This method is used to produce commodity and. blown films extrusion is one of many polymer manufacturing processes. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The extruder consists of a screw that conveys the resin through a heated barrel. The blown film industry has evolved from monolayer film structures to multilayer. solve five common problems in blown film coextrusion.

from weighbatch.com

The extruder consists of a screw that conveys the resin through a heated barrel. The blown film industry has evolved from monolayer film structures to multilayer. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The first step in blown film manufacturing is extrusion. blown film processing. blown films extrusion is one of many polymer manufacturing processes. solve five common problems in blown film coextrusion. This method is used to produce commodity and.

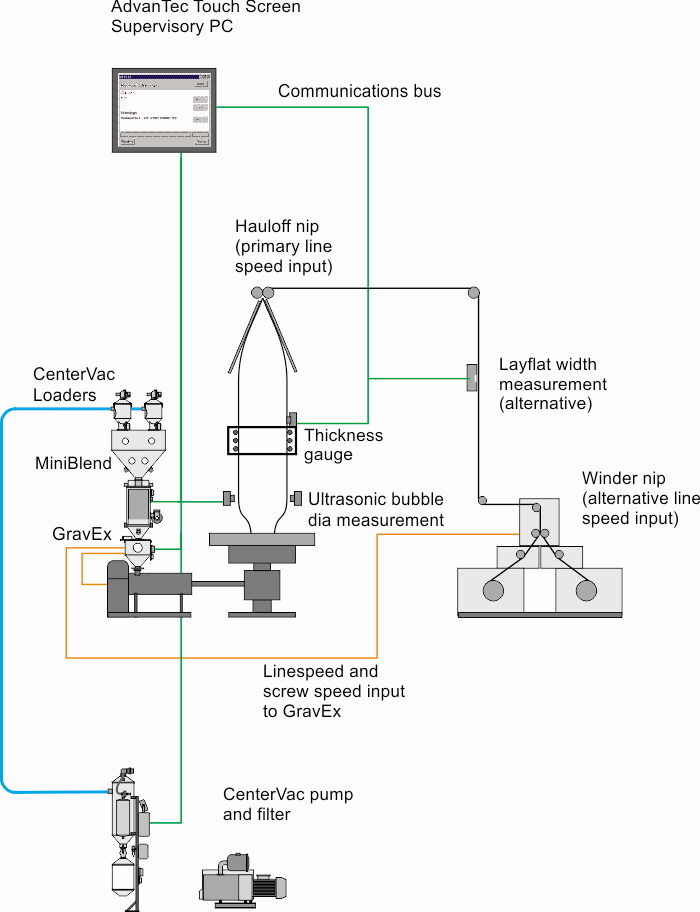

Blown Film Extrusion Control

Polyethylene Blown Film Extrusion blown films extrusion is one of many polymer manufacturing processes. blown film processing. blown films extrusion is one of many polymer manufacturing processes. This method is used to produce commodity and. solve five common problems in blown film coextrusion. The extruder consists of a screw that conveys the resin through a heated barrel. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. The blown film industry has evolved from monolayer film structures to multilayer. The first step in blown film manufacturing is extrusion. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder.

From fillplas.com

Blown film extrusion and CaCO3 filler masterbatch in blown film extrusion Polyethylene Blown Film Extrusion Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. blown films extrusion is one of many polymer manufacturing processes. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. The first step in blown film manufacturing is extrusion.. Polyethylene Blown Film Extrusion.

From hnpenghuimachine.com

Plastic HDPE PE PP Three Layer Film Blow Blowing Machine Polyethylene Blown Film Extrusion solve five common problems in blown film coextrusion. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. This method is used to produce commodity and. blown films extrusion is one of many polymer manufacturing processes. blown film extrusion system is, in fact, one of the most. Polyethylene Blown Film Extrusion.

From www.plastar-machine.com

Fivelayer Coextrusion Blow Film Machine PLASTAR Machinery Polyethylene Blown Film Extrusion The first step in blown film manufacturing is extrusion. blown films extrusion is one of many polymer manufacturing processes. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. blown film processing. The blown film industry has evolved from monolayer film structures to multilayer. Plastic resins, such as. Polyethylene Blown Film Extrusion.

From pemachine.en.made-in-china.com

Durable and Well Made Three Layers CoExtrusion Biodegradable Polyethylene Blown Film Extrusion The extruder consists of a screw that conveys the resin through a heated barrel. blown films extrusion is one of many polymer manufacturing processes. The first step in blown film manufacturing is extrusion. blown film processing. solve five common problems in blown film coextrusion. The blown film industry has evolved from monolayer film structures to multilayer. Web. Polyethylene Blown Film Extrusion.

From www.ferben.com

Blown film extrusion Polyethylene Blown Film Extrusion blown film processing. The blown film industry has evolved from monolayer film structures to multilayer. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. solve five common problems in blown film coextrusion. blown film extrusion system is, in fact, one of the most complex and sensitive. Polyethylene Blown Film Extrusion.

From zhengxinmachinery.en.made-in-china.com

Plastic Film Wrapping Blowing Machine Low Pressure HighDensity Polyethylene Blown Film Extrusion blown films extrusion is one of many polymer manufacturing processes. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. This method is used to produce commodity and. solve five common problems in blown film coextrusion. blown film processing. blown film extrusion system is, in fact,. Polyethylene Blown Film Extrusion.

From www.alamy.com

Plastic Extrusion, Polyethylene plastic film blowing machine Stock Polyethylene Blown Film Extrusion Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. blown film processing. solve five common problems in blown film coextrusion. The blown film industry has evolved from monolayer film structures to multilayer. The extruder consists of a screw that conveys the resin through a heated barrel. Web. Polyethylene Blown Film Extrusion.

From www.mercplastics.com

Cast and Blown Film Extrusion Mercury Plastics Inc Polyethylene Blown Film Extrusion The blown film industry has evolved from monolayer film structures to multilayer. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The first step in blown film manufacturing is extrusion. The extruder consists of a screw that conveys the resin through a heated barrel. solve five common problems. Polyethylene Blown Film Extrusion.

From windsormachines.com

7layer blown film extrusion line Blown film line Windsor Machines Polyethylene Blown Film Extrusion The first step in blown film manufacturing is extrusion. blown films extrusion is one of many polymer manufacturing processes. The blown film industry has evolved from monolayer film structures to multilayer. blown film processing. The extruder consists of a screw that conveys the resin through a heated barrel. This method is used to produce commodity and. Plastic resins,. Polyethylene Blown Film Extrusion.

From www.alibaba.com

High /low Density Polyethylene Blown Film Extrusion Lines China Polyethylene Blown Film Extrusion The extruder consists of a screw that conveys the resin through a heated barrel. blown film processing. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. blown films extrusion is one of many polymer manufacturing processes. The blown film industry has evolved from monolayer film structures to. Polyethylene Blown Film Extrusion.

From fillplas.com

Blown Film and How it works? Polyethylene Blown Film Extrusion The extruder consists of a screw that conveys the resin through a heated barrel. The blown film industry has evolved from monolayer film structures to multilayer. The first step in blown film manufacturing is extrusion. blown film processing. solve five common problems in blown film coextrusion. blown films extrusion is one of many polymer manufacturing processes. Plastic. Polyethylene Blown Film Extrusion.

From polystarinc.com

Polyethylene Film Extrusion Polystar Inc Polyethylene Blown Film Extrusion This method is used to produce commodity and. blown film processing. solve five common problems in blown film coextrusion. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. The blown film industry has evolved from monolayer film structures to multilayer. The first step in blown film manufacturing. Polyethylene Blown Film Extrusion.

From www.mercplastics.com

Cast and Blown Film Extrusion Mercury Plastics Inc Polyethylene Blown Film Extrusion This method is used to produce commodity and. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. blown film processing. The blown film industry has evolved from monolayer film structures to multilayer. solve five common problems in blown film coextrusion. blown films extrusion is one of. Polyethylene Blown Film Extrusion.

From www.dreamstime.com

Blown Film Extrusion Plastic Bag Making Machine Stock Image Image of Polyethylene Blown Film Extrusion blown films extrusion is one of many polymer manufacturing processes. This method is used to produce commodity and. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. The. Polyethylene Blown Film Extrusion.

From www.directindustry.com

Blown film coextrusion line REX series Windsor Machines Limited Polyethylene Blown Film Extrusion The blown film industry has evolved from monolayer film structures to multilayer. The extruder consists of a screw that conveys the resin through a heated barrel. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. blown film extrusion system is, in fact, one of the most complex and. Polyethylene Blown Film Extrusion.

From www.youtube.com

Polyethylene Film Extrusion Machine YouTube Polyethylene Blown Film Extrusion blown film processing. blown films extrusion is one of many polymer manufacturing processes. The blown film industry has evolved from monolayer film structures to multilayer. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The first step in blown film manufacturing is extrusion. solve five common. Polyethylene Blown Film Extrusion.

From weighbatch.com

Blown Film Extrusion Control Polyethylene Blown Film Extrusion blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing technologies. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. The first step in blown film manufacturing is extrusion. The blown film industry has evolved from monolayer film structures to. Polyethylene Blown Film Extrusion.

From www.pefilmblowingmachine.com

3 Layers Co extrusion Low Density Polyethylene film Blown Equipment Polyethylene Blown Film Extrusion The first step in blown film manufacturing is extrusion. The blown film industry has evolved from monolayer film structures to multilayer. Plastic resins, such as polyethene (pe) or polypropylene (pp), are melted and formed into a molten state using an extruder. blown film extrusion system is, in fact, one of the most complex and sensitive of all plastics processing. Polyethylene Blown Film Extrusion.